The technology is based on pneumatic propulsion – the air is pressurized by high energy efficiency stationary fans, through a duct located within the elevated guideway. The air pushes or pulls the propulsion plate attached to the vehicle, which moves along a truck (platform on steel wheels) on rails.

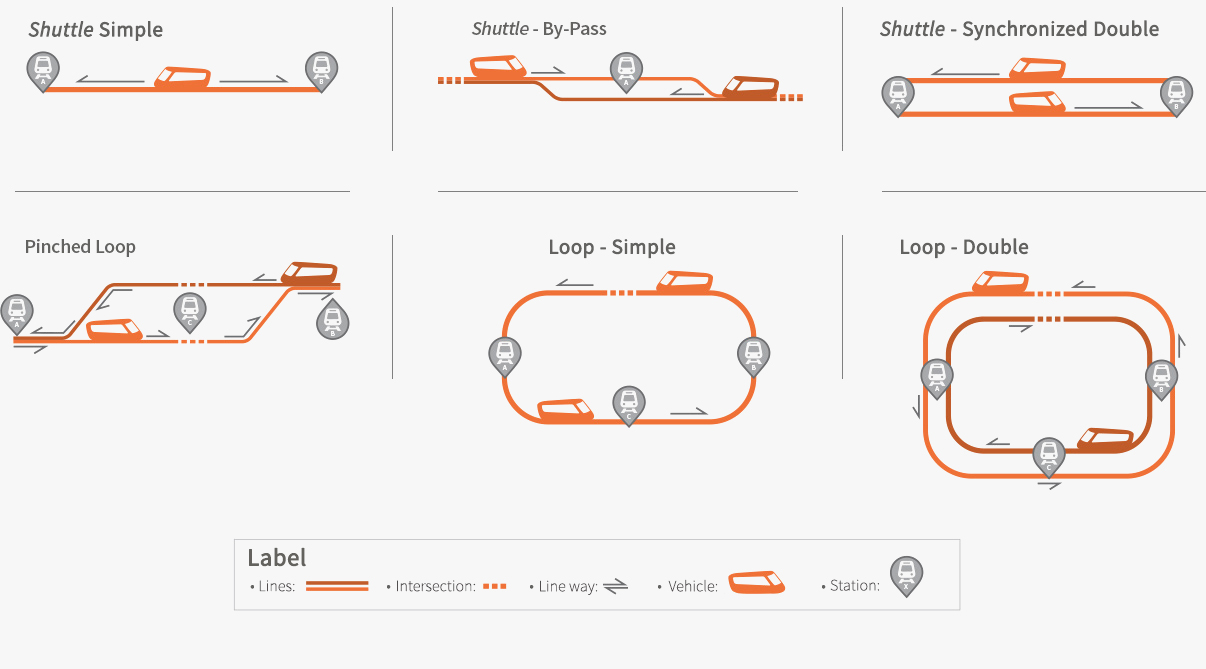

The Aeromovel System fits into a broad category, called the Automated Guideway System, also known as Automated Transit System (ATS), which refers to the fully automated passenger transport systems on an exclusive track. As such, the Aeromovel meets everything from mass urban transport demands - in typical configurations of dual elevated rails, with maneuvers at terminals with detours -, to smaller systems. Some types of applications are: loop configuration, shuttle, double shuttle, distances, and double rails, among others. There is an important subclass of the two AGT/ATS systems, known as the Automated People Mover (APM). People movers≤/ are widely known for their most notorious applications in airports.

Slim elevated guideway;

Light vehicle using rail wheels;

Privileged view for passengers during the journey;

Very low dead weight per passenger;

Compact stations easy to insert in existing environments;

Pneumatic propulsion with stationary engines and propellers;

Easy track insertion and integration within urban network;

Segregated tracks with fully automated operation;

Low implementation, operating and maintenance costs;

Compliance with international technical regulations;

Low energy consumption;

Capacity to carry up to 40,000 passengers per hour/direction,

according to project demand;

The elevated guideway creates a new space, freeing the areas at ground level for other functions and activities;

Speed of up to 80 km per hour;

High availability frequency, with typical headway of 90 to 120 seconds;

Vehicle acceleration of up to 1.10 m/s2 and deceleration of 1.0 m/s;

Adjustable operating parameters by selecting pre-defined speed and headway profiles.

Rolling system equipped with efficient noise and vibration insulator;

Impossibility of collision between vehicles due to compression

of the air inside the propulsion duct;

Redundant control systems;

Safety against derailment and tipping thanks to a propulsion plate anchored inside the elevated guideway;

Compliance to earthquake regulations;

Emergency exists to the track on both ends of the vehicle;

Stations with platform doors;

Optional emergency exists via the side boarding and exiting doors, using emergency walkways;

Generators guarantee operation even during power failures.

Clean technology, with electric motors and no pollutant emissions;

Stationary electric motors and fans with acoustic insulation (55 dBA);

Minimal occupation of ground space;

Project in full accordance with environmental legislation;

Slim elevated structures, with modern design of low visual impact;

No electromagnetic impact.

Automated acceleration and deceleration, according to

international comfort standards;

Universal accessibility, with space for wheelchair users and the elderly;

World Class –APM guided transport with fully automated vehicle operation on exclusive tracks;

Ease of access to stations.

Silent vehicles, with no engine noise;

The same characteristics that allow reaching very low capital costs also provide equally low operating and maintenance costs over the years, considering a reduced number of professionals needed, and also for using non-proprietary spare parts (off-the-shelf). This is only possible due to the successful combination of autonomous, light vehicles with no embedded engines, with the overall simplicity of the system and its main components.