The elevated guideway comprises prefabricated beams and pillars, allowing a rapid and uncomplicated assembly. It combines the functions of supporting the rails, the air duct for vehicle propulsion and safe passenger access to the next station in case of emergencies. The minimum curve radius of 25 meters and the track beam spans, varying from 10 to 35 meters, ensure easy insertion of the Aeromovel within urban layouts, with no need for resettlements. The height of the track, usually between 4.5 and 20 meters, can be raised enough to pass over existing bridges and railways.

The Aeromovel System has a patented technology for the design for its track detour devices. The deviation is a reverse circular curve with a radius of 27 meters, equipped with four actuators for the five mobile rails that comprise it.

Each rail features a double locking system for all positions which, together with the sensor and control subsystem, ensures complete System safety.

The vehicle is characterizes by its reduced dead weight, mainly because it does not carry on board the equipment associated to the propulsion. It comes in one, two, three and four carriage versions, with a capacity of up to 600 passengers in the latter. Each one features a 4-wheel truck, with an outer steel ring and an inner layer of resilient material, and an anti-derailment system that connects the carriage to the elevated guideway structure by means of counter-wheel sets placed inside the air duct.

Each carriage has two doors on each side, allowing for a safe, comfortable and fast boarding.

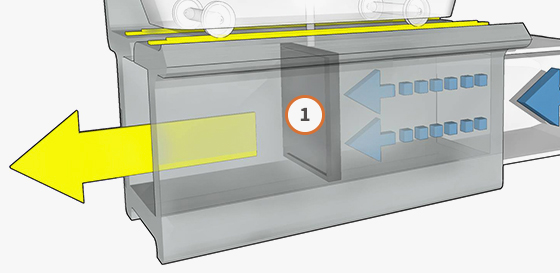

The Aeromovel System does not traction the wheels and uses the propulsion outside the vehicles, controlling air pressure, direction and speed by means of stationary fans and its control valves. This is a significant benefit, compared to the use of the conventional wheel/rail system, which has huge limitations in overcoming steep slopes (up to 12%) and curves with small radius (up to 25 meters).

The propulsion uses industrial fans, usually elevated and located alongside the passenger stations. Sectional insulation valves are installed on the elevated guideway, creating exclusive pneumatic circuits for individual control of each vehicle, ensuring a safe and intrinsic distance between vehicles. Generator sets can be used to ensure uninterrupted operation of the System.

The industrial fans used in the Aeromovel System are unique and have high energy efficiency. They are installed inside the stations and activated by electric motors controlled by frequency inverters that allow the equipment to run at an optimal level, regardless of the vehicle operating system (acceleration or cruising). The maximum air pressure level for operation is 0.2 bar.

The fan consists of four airflow control valves that are responsible for the almost instantaneous switching between "pressure" (positive pressure) and "suction" (negative pressure) modes.

Located in one of the stations, or close to the line, the cutting-edge Aeromovel control system is operated remotely. Based on highly reliable modular technology, it allows the adjustment of varied operating parameters, such as speed, acceleration, vehicle fleet, headway, length of stops at stations and others. The Aeromovel control features an ATC System, with Automatic Train Protection (ATP) and Automatic Train Operation (ATO), and an Automatic Train Supervision (ATS) system for interface with the operator.